SOLENOID VALVES operate by utilizing an electric current. When activated, the pilot orifice opens, allowing the medium to pass through. A normally open valve has similar components, but works in the opposite manner. When an electric current is applied to the pilot orifice, it blocks the passage D, preventing water from accumulating in the cavity C. Therefore, the pressure difference on either side of the valve opens the pilot orifice, enabling the medium to flow from the inlet port to the outlet port.

Depending on the type and size of the solenoid valve, you will find many different types and configurations. The basic types of solenoid valves are direct operated solenoid valves and indirect operated solenoid valves. Depending on the application, you may also need to choose between a rotary or a ball valve. Lastly, a directional or butterfly valve is another type.

A solenoid valve is used in several applications. In refrigeration systems, the valves reverse the flow of refrigerants to help maintain a comfortable temperature. Solenoid valves are also found in irrigation systems, dishwashers, washing machines, and air conditioning systems. They are also found in medical equipment and automatic door locks. Other applications include water tanks, which use the solenoid valve in combination with a float switch to control inflow and outflow.

Solenoid valves are used in a number of applications. The most common examples are refrigeration systems. They control the flow of refrigerants and help keep temperatures comfortable in the summer or warm in the winter. Other applications include irrigation systems, automatic door locks, and car washes. The mechanical parts of these valves should be compatible with the medium in order to prevent damage to the equipment. Solenoid valves are used in all types of settings, including industrial, medical, and household equipment.

A solenoid valve is an electrically operated valve that replaces the need for manual valve operation. The valve is operated by an electromagnetic solenoid coil. There are three types of solenoid valves: in-direct acting, forced-lift piston, and direct-acting. The latter is the most common type. It has two major types: in-direct and indirect. The first type is a closed-acting one.

The directional solenoid valve is another type of solenoid valve. This type uses a power signal to open and close the corresponding chamber. A bidirectional valve also allows for control by using the same signal. However, the bidirectional version of a solenoid valve has several advantages. Because of its bidirectional design, it is flexible and can be installed anywhere. Its inherent flexibility allows for easy integration into a variety of applications.

The first type of solenoid valve is a direct-acting type. A typical direct-acting model is designed to be direct-acting. In a bidirectional arrangement, the pilot will turn a single solenoid valve to close or open. In a bidirectional configuration, the valve is open when there is pressure in the lower chamber. The spring holds the diaphragm closed.

The flow coefficient of a SOLENOID VALVE is the measurement of the flow capacity. In the United States, the flow coefficient represents the volume of fluid flowing through the valve at a pressure drop of 1 psi. Its open and closed ranges are measured in U.S. gallons. A bidirectional solenoid valval is often operated by a pilot, which controls the flow.

A direct-operated solenoid valve is the most common type. A direct-operated NC solenoid valve can be used for many different applications. This type of solenoid valve is best for applications requiring precise control over pressure. It is a good choice for pneumatic and hydraulic applications. Solenoid valvings are ideal for a variety of applications. They have low pressure requirements and high pressure capability.

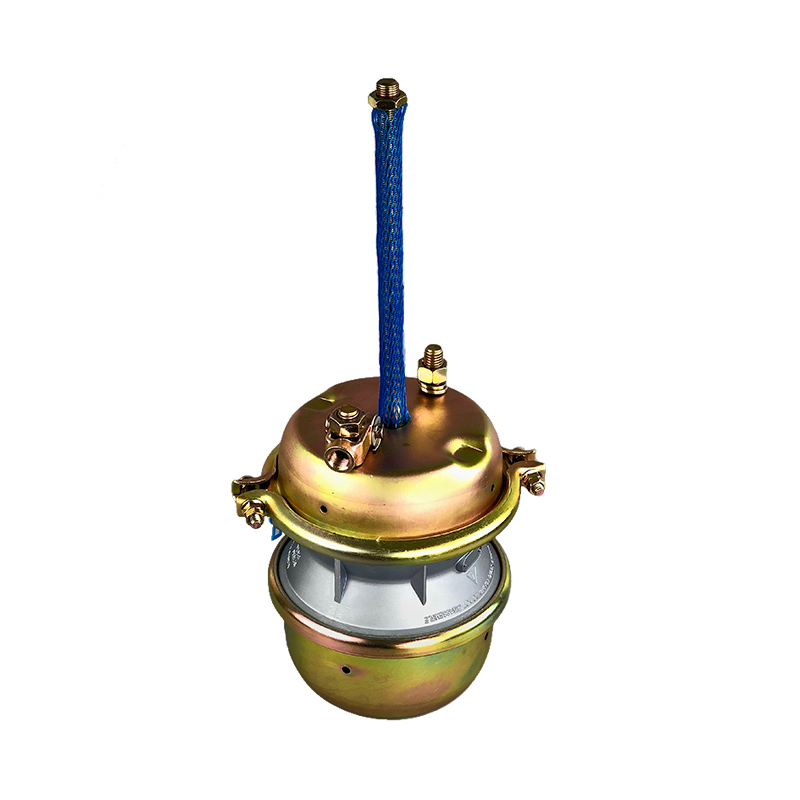

A basic SOLENOID VALVE is made up of four parts. A coil mounted on the valve body receives electrical impulses and converts these into mechanical movements. The coil moves the plunger and opens or closes the valve. A second part is the bonnet. The two main parts of a Gas Solenoid VALVE are shown in the diagram below. The inlet and outlet connections on a Solenoid VALVE are made by connecting a spring and a coil.