Desiccant-type in-line filtration system

The desiccant-type in-line braking air dryer has a filter element that is generally cylindrical and has end blocks that are locally formed axial projections located evenly about the upper perimeter of the filter. This filter element is made of a desiccant-like material, such as expanded aluminum foil mesh. Expanded aluminum foil has a thickness of 0.003 inches and can be expanded to form open patterns of 0.050 inch width.

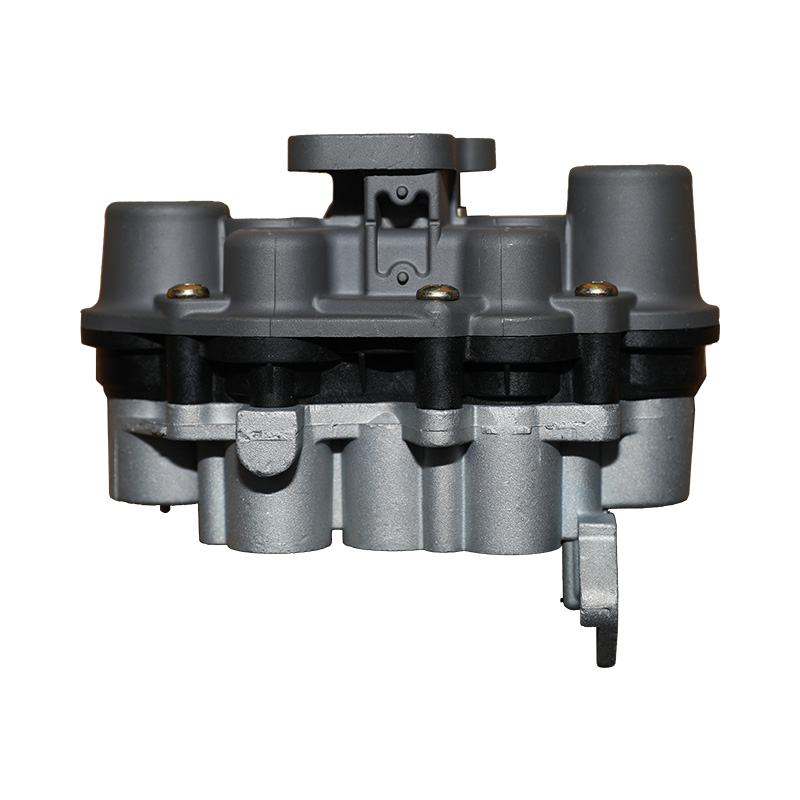

The desiccant-type in-line braking air dryer comprises a desiccant-type material that is pressed by a spring. A cloth sack retains the desiccant bed in a densely packed condition. The spring helps to retain the desiccant bed in its compacted state. The desiccant-type in-line filtration system for brake air dryer comprises two components: an outer shell and an inner sleeve.

Desiccant cartridge

Choosing a new desiccant cartridge for your brake air dryer is an important step in preventing brake valves from rusting or corroding. While many companies offer value cartridges, the original manufacturer's brand guarantees quality performance and a competitive price. If you're in a pinch, value cartridges are an affordable option. Aftermarket options, however, are not a safe bet. You'll risk increased service costs and downtime with aftermarket products.

The desiccant is the most important part of an air dryer cartridge. However, not all desiccants are created equal. The desiccant you select must be suitable for the brake air dryer application, as it's subjected to high temperatures, wild temperature fluctuations, and pressure cycling. When the desiccant fails, it can clump and even become powder and contaminate the brake valves.

Initial purge

It is important to maintain a brake air dryer to prevent the clogging of your system. Your brake air dryer takes moisture and oil out of the air before it reaches your working parts. Poorly maintained brake air dryers can lead to failure of brakes. Properly maintained brake air dryers protect your brake system and reduce downtime. The initial purge for brake air dryer can be as simple as draining the air tanks and replacing the desiccant cartridge.

If you notice a high amount of oil leaking from your system, your brake air dryer might be faulty. To test if this is the case, run your car with its engine running for at least a few seconds. If you notice a low pressure in your braking system, the compressor will cut off. If you can detect air coming out of the exhaust port, the purge valve may be faulty. If you find air leaking from the tank drain valve, the problem may lie elsewhere in the brake system.

Cleaning

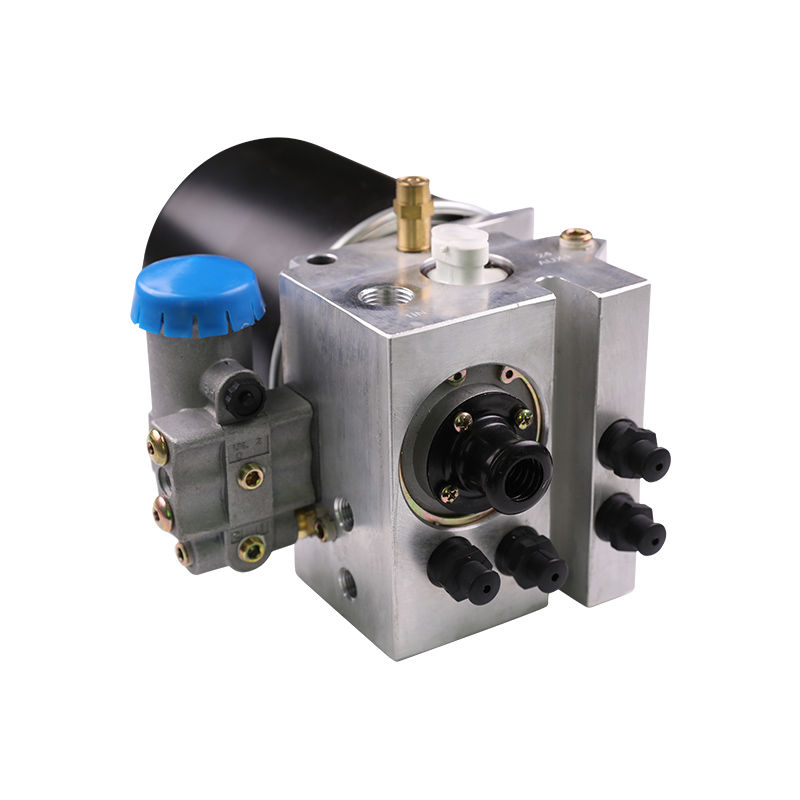

Besides reducing the chances of brake system problems, the brake air dryer also improves the performance of the system. It is installed between the air brake reservoir and the compressor. Brake air dryers are important parts of the braking system, as they help to remove moisture and other contaminants from compressed air. Air dryers differ in size, design, and construction, but they all function the same way: They remove water and other contaminates from compressed air to provide clean oxygen to brake components, reducing maintenance costs and extending the service life of the system.

A brake air dryer removes contaminants and water from the brake system, which can freeze and cause failure in cold weather. This device is plumbed between the compressor and first tank in older systems. The air from the compressor cools in the wet tank, and the moisture from the air condenses in the cold metal of the tank. By regularly draining and cleaning the air dryer, you can prevent brake system failures and extend the life of the air components.