Using an Air Dryer in your trailer can be a beneficial feature to help keep your trailer dry. However, there are several factors that need to be considered in order to ensure the air dryer is operating properly.

Desiccant

Generally, desiccant is derived from aluminum oxide and silicon dioxide. The material has high affinity for water and removes excess moisture from the air. It is used in air dryers, which are used in compressed air systems. The desiccant of present invention is particularly useful in trailer air dryers.

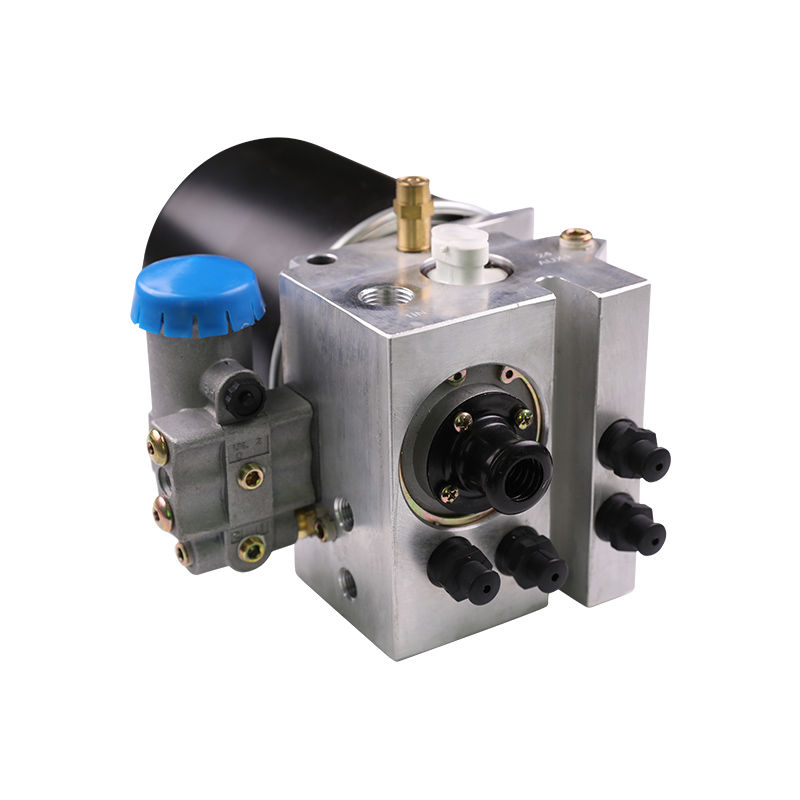

In accordance with one aspect of the present invention, an air dryer 10 comprises a body  assembly 14 and a desiccant cartridge 12. The body assembly 14 is connected to a passageway in the air dryer housing. The desiccant cartridge 12 comprises a desiccant bed 24 and a desiccant cartridge load plate 12. The retention bolt 84 provides a flow passageway for air through the air dryer. The retention bolt is positioned in a central bore 104 of the body assembly. It is accessible from the bottom of the body assembly and threads into a centrally disposed threaded bore in the desiccant cartridge load plate. The retention bolt also has a hollow interior passage that communicates with the discharge bore. The retention bolt also has a driving head accessible for rotating.

assembly 14 and a desiccant cartridge 12. The body assembly 14 is connected to a passageway in the air dryer housing. The desiccant cartridge 12 comprises a desiccant bed 24 and a desiccant cartridge load plate 12. The retention bolt 84 provides a flow passageway for air through the air dryer. The retention bolt is positioned in a central bore 104 of the body assembly. It is accessible from the bottom of the body assembly and threads into a centrally disposed threaded bore in the desiccant cartridge load plate. The retention bolt also has a hollow interior passage that communicates with the discharge bore. The retention bolt also has a driving head accessible for rotating.

Filtering system

Providing adequate braking is a critical task for heavy-duty trucks. They rely on compressed air to operate the brakes, and are therefore susceptible to leaks, which can lead to braking issues. For this reason, an air dryer is an important safety component.

A surprisingly small component, an air dryer is comprised of a housing containing a series of parallel passages. Each passage includes a small amount of dry material to act as a moisture buffer. The housing and the passages are preferably made from aluminum extrusion.

The air dryer also boasts a bypass arrangement. This ensures that the dryer assembly remains attached to the trailer braking assembly during normal braking, but removes it from the line during emergency braking. The aforementioned bypass enables the dryer to perform its braking tasks without requiring the braking system to operate at full throttle.

Aside from the above mentioned dry materials, there is also the obvious. For instance, a trailer air dryer may include a replaceable filter cartridge. This filter should be replaced at appropriate intervals, to ensure that it performs its duty correctly.

Maintenance requirements

Depending on the type of air dryer you use, there may be modifications required. For example, some air dryers use a lubricant that must be pumped into the air system on a regular basis. If this is not performed, it could contribute to premature damage in various components. For example, oil can deteriorate the seals, which can cause leaks. To avoid this, keep the air system clean and dry.

Depending on the type of air dryer, you may need to replace the filter. For example, if you have an oil-coalescing cartridge, you may need to replace it every year. In other cases, you may only need to replace it once every three years. In general, cartridges last two to three years for normal over-the-road applications, and one to three years for regional applications.

In addition to the replacement of the filter, you may need to install other air dryer accessories, such as an oil ejection valve. Oil in the air system can contribute to premature damage in various components, so removing it is important.