In the vehicle braking system, the air brake valve is a core component, and the choice of its installation position is crucial to the stability of the braking system. The stability of the braking system is directly related to the safety and reliability of vehicle driving. Therefore, various influencing factors must be fully considered during the design and installation process.

Basic functions and working principles of air brake valves

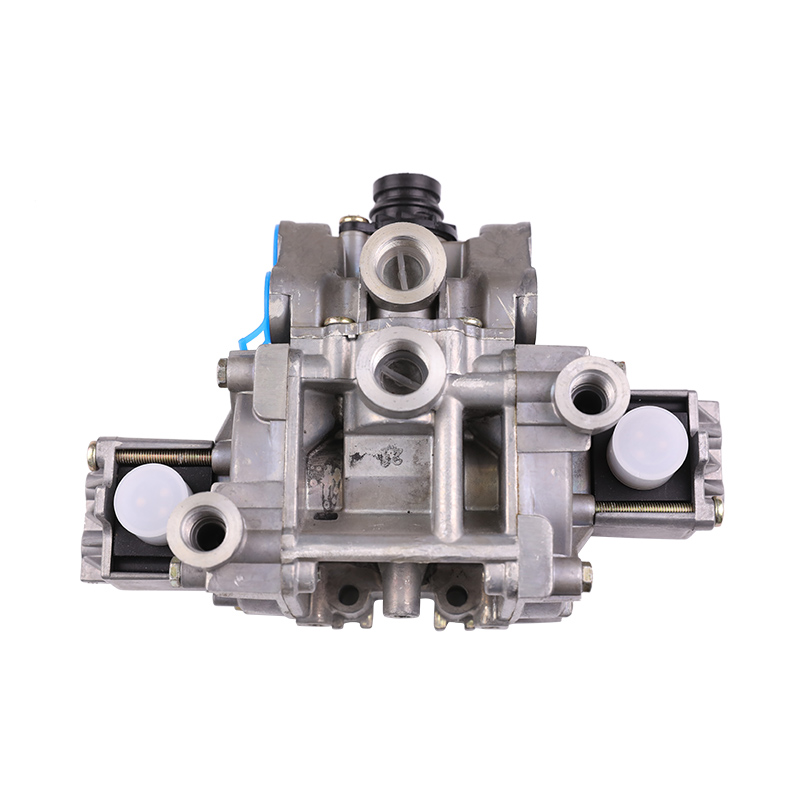

The air brake valve is a key component in the pneumatic brake system, which is mainly responsible for controlling the in and out of compressed air, thereby achieving precise adjustment of the brake pressure. When the driver steps on the brake pedal, the air brake valve responds quickly, delivers compressed air to the brake cylinder, pushes the piston to move, and thus generates braking force. In this process, the sensitivity and accuracy of the air brake valve are particularly important, which directly affects the braking response time and the distribution of braking force.

Impact of installation position on the stability of the braking system

Impact of vibration and shock

If the installation position of the air brake valve is close to the vehicle power system or vibration source, such as the engine and drive shaft, it may be affected by vibration and shock. Long-term vibration and shock will cause the internal parts of the air brake valve to loosen, wear or even damage, thereby affecting its sealing performance and adjustment accuracy. Once the air brake valve fails, the stability of the brake system will be seriously threatened, which may cause serious problems such as brake failure or uneven distribution of braking force.

Impact of temperature environment

During the operation of the vehicle, the brake system generates a lot of heat. If the air brake valve is installed too close to the heat source, such as the brake drum or exhaust system, its internal parts may expand, deform or age due to high temperature, affecting its normal operation. In addition, the high temperature environment may cause the moisture in the compressed air to condense, forming scale or ice crystals, further affecting the adjustment performance and stability of the air brake valve. Therefore, in the design stage, it is an important measure to ensure the normal operation of the brake system to reasonably select the installation position of the air brake valve to avoid overheating.

Spatial layout and pipeline length

The installation position of the air brake valve is also limited by the spatial layout of the vehicle. If the installation position is too compact, the pipeline may be too long or too bent, which will not only increase the flow resistance of the compressed air in the pipeline, but also cause gas vortex and pressure loss, thereby affecting the stability and response speed of the brake system. Too long pipelines may also increase the failure points and maintenance difficulties, reducing the overall reliability of the brake system. Therefore, a reasonable spatial layout design is the basis for ensuring the efficient operation of the air brake valve.

Electromagnetic interference and protection

The electronic control system in modern vehicles has become an important part of the brake system. If the air brake valve is installed close to the source of electromagnetic interference, such as the generator and ignition system, it may be interfered by electromagnetic waves, resulting in signal distortion or transmission failure. This situation will not only affect the normal operation of the brake system, but may also cause safety hazards. Therefore, taking effective protective measures to reduce the impact of electromagnetic interference on the air brake valve is an important part of improving the reliability of the brake system.