You may have heard of the tilted disc check valve. This water check valve is made of metal and resilient seats and has a swing range of 60 to 90 degrees. Its tendency to slam is due to the inertia of the disc and friction in the packing. Moreover, this type of valve provides low head loss. Listed below are some of the other common types of check valves.

Tilting disc check valve

The Tilting Disc Check Valve is designed for medium to low-pressure applications. The valve's design features a low-stroke opening range and a full-flow area that maximizes flow efficiency. This design helps reduce flow reversal and water hammer, two common problems with other valve types. Its offset seating technology lifts the disc out of its seat during opening and lowers it during closing.

The Tilting Disc Check Valve is installed horizontally or vertically to maximize flow and minimize pressure. The right side should face upward. This valve's low mass helps mitigate water hammer. It closes quickly and without creating a return pressure wave. This design minimizes pressure drop, even at low flow rates. However, it may be more difficult to repair and maintain than other check valves. Therefore, it is important to learn more about Tilting Disc Check Valve.

When installed correctly, the Tilting Disc Check Valve ensures safety. The valve's disc automatically reverts to its seating position when the pressure drops below a certain level. Unlike other check valves, these devices require no actuators, handwheels, or other mechanisms to operate. Their operation is automatic and is controlled by the pressure difference between the fluids being suction pressure and outlet pressure. The valve closes when backflow occurs.

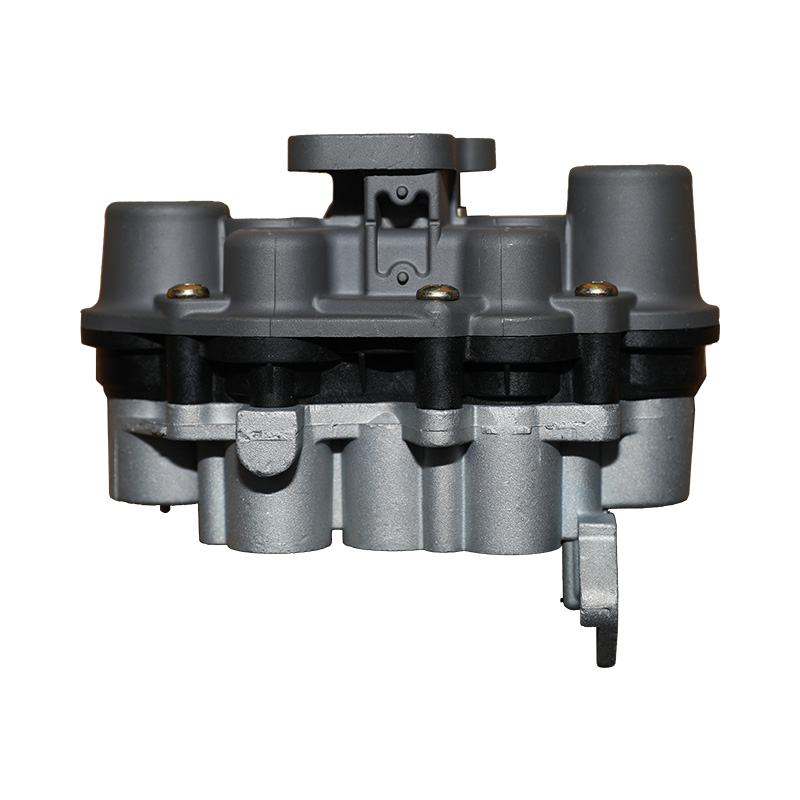

Swing check valve

A swing check valve is a safety device that prevents backflow of liquid in horizontal piping systems. Its unique spherical joint attachment enables the flap to swing through 360 degrees without leaking. It is also designed with a limit switch for remote monitoring. There are several advantages of this valve type. Read on to discover more about the advantages of this type of valve. And don't forget to check out our swing check valve review.

The swing check valve is an excellent choice for gate valve systems. Its compact and simple design allows it to work efficiently with minimal pressure loss across the valve. This valve style has a hinged disc that opens when liquid enters it and a seat ring that prevents liquid from passing through it. The disc's seating surface is tilted slightly, providing a positive seal and low fluid resistance. It is especially suitable for water and wastewater systems, as its short disc stroke minimizes the shock that the valve experiences when it closes.

The durability of swing check valves is unsurpassed. They withstand tough conditions. The materials used for them depend on the media to be pumped, the pressure levels, and the amount of wear and corrosion. Some materials are incredibly strong and resistant to corrosion and wear, but are also more expensive. In general, iron is the best material for swing and spring check valves. Iron has good shock absorption and corrosion resistance, and is extremely lightweight.

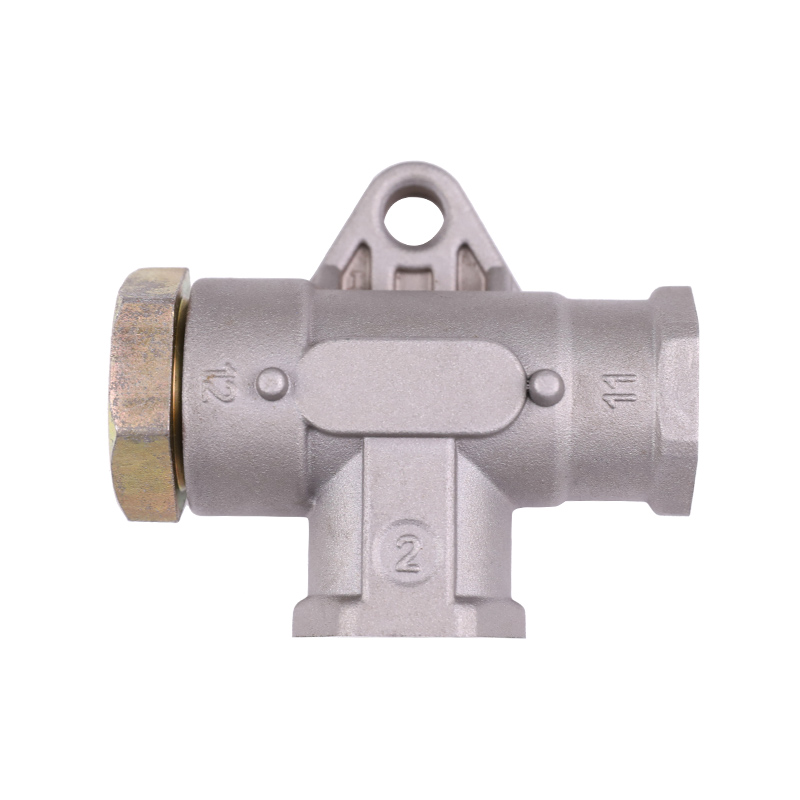

Non-slam check valve

The Non-slam check valve is a type of high-pressure check valve. These valves have a piggable seat and have high pressure and temperature ratings. The metal construction of these valves prevents leakage, and the non-slam design is ideal for applications involving corrosive products. The non-slam check valve can be used in a variety of industrial processes, such as pipeline applications.

A non-slam check valve works by using differential pressure to prevent backflow of fluid in a pipeline. When the pressure upstream is high enough, the disc is compressed to open the valve. Once the disc opens, fluid passes through the valve and flows in one direction. As the upstream pressure is reduced, the pressure in the pipe closes the valve, preventing the flow of fluid in the opposite direction. This type of check valve is not recommended for use with high viscosity or solid particles.

A non-slam check valve is also better for pipelines than a swing check valve. If the swing check is not applied properly, it could break the hinge pin, allowing water hammer to occur. In addition, the backflow energy from the swing check must be dissipated in the form of water hammer. The non-slam check valve eliminates this problem. Its coiled spring is downstream of the valve disk and moves the disk toward the seat when the flow slows.