A truck's Air Brake Valve must be operated with the correct pressure to prevent a crash. In addition, it must be designed to protect the truck's air brakes from corrosion. Several types of valves are available, including crack pressure, Modulating control valves, Quick release valves, and Relay emergency valves.

Crack pressure

The crack pressure of a truck air brake valve is measured in pounds per square inch (psi). All valves, regardless of quality, should be the same. For example, a new high-quality valve rated for four psi might open at 3.5 to 4.5 psi, while an older valve rated for 7.5 psi may require as much as 10.5 psi to operate. Crack pressure varies, in part, because of the stiffness of the piston-return spring.

Whether you're driving a large truck or a small cargo van, you'll need to understand how these air brake valves function. Relay valves work in the same way as traditional air brake valves, but they apply brake pressure to the rear wheels first. These valves are commonly found on large trucks with a long wheelbase.

Modulating control valves

Modulating truck air brake valves are incorporated into the brake system to provide braking assistance. These valves control the flow of air, pressure, and temperature. The type of control valve used depends on the pipe size, flow media, and process conditions. The following is a description of some of the valve types and their purposes.

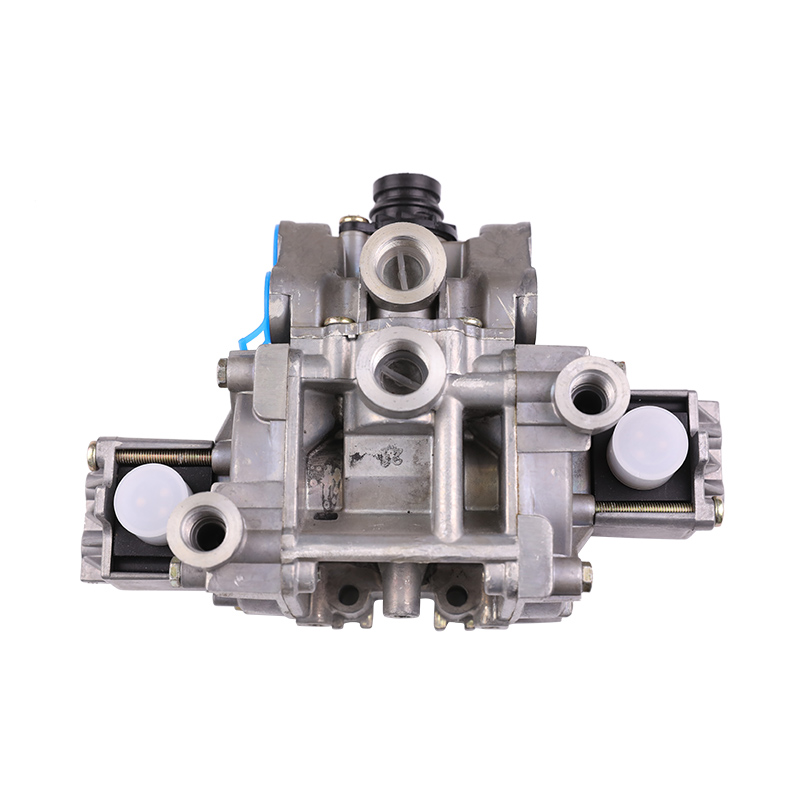

In-line modulating truck air brake valves are designed to operate under pressure applied at the valve supply and at a preselected pressure level. They are installed in a series of shims and each individual valve contains an o-ring, mounting bolts, and a grease pack.

Quick release valves

Quick release truck brake valves help prevent vehicle accidents by reducing the pressure on the brakes. These valves operate in an air brake system and are used in trucks and tractors. The terms quick release valve and combined limiting valve are interchangeable and serve similar purposes. These valves reduce front-wheel brake pressure under slippery road conditions. They also protect the air brake system when trailer breakaway or leakage develops.

Quick release valves are located close to the brake chamber, which helps reduce the amount of lag. Brake lag is the amount of time that passes between applying the brakes and releasing them. This lag increases with increasing pedal pressure, but quick release valves reduce this lag.

Relay emergency valve

A Relay emergency valve for a truck's air brake valve is used to ensure the safety of the truck's braking system in an emergency. These emergency valves are available for a variety of vehicles, including commercial trucks, heavy trucks, and trailers. They work by increasing air pressure in the reservoir of each brake to prevent over-inflated suspensions and brakes.

Relays are air-operated valves that control the brakes at the rear of a heavy truck. They help speed up the application of the rear-brake. As the air travels further to the rear of the vehicle than to the front, relay valves enable faster rear-brake application.

Double diaphragm safety actuator

A double diaphragm safety actuator is used to control the air brake valve in a truck or trailer. This type of safety actuator is less expensive than a piston type actuator. However, it does have some disadvantages. For example, a double diaphragm actuator has a shorter stroke than a piston type actuator, which can cause brake fade under the wrong application.

In its normal function, a double diaphragm safety actuator for a truck air brake valve has two chambers: one forward chamber and one rearward chamber. The forward chamber normally brakes the rear wheels of the vehicle, and it receives air at service pressure through brake line 23. The diaphragm pushes against a centrally supported output shaft 27 and rotates conventional slack adjuster mechanisms 30. Meanwhile, the emergency brake chamber 26 receives air at supply pressure from brake line 36 in fluid communication with delivery port 33 of inversion valve 12.