A brake air dryer is a component of a commercial vehicle's air brake system that is designed to remove moisture and contaminants from the compressed air used to operate the brakes. It is typically used on heavy-duty trucks, buses, and trailers.

The air brake system in a commercial vehicle uses compressed air to activate the brakes. This compressed air contains moisture and contaminants that can cause corrosion and damage to the brake components, reducing their effectiveness and lifespan. A brake air dryer helps to remove this moisture and contaminants, ensuring that the brake system operates reliably and effectively.

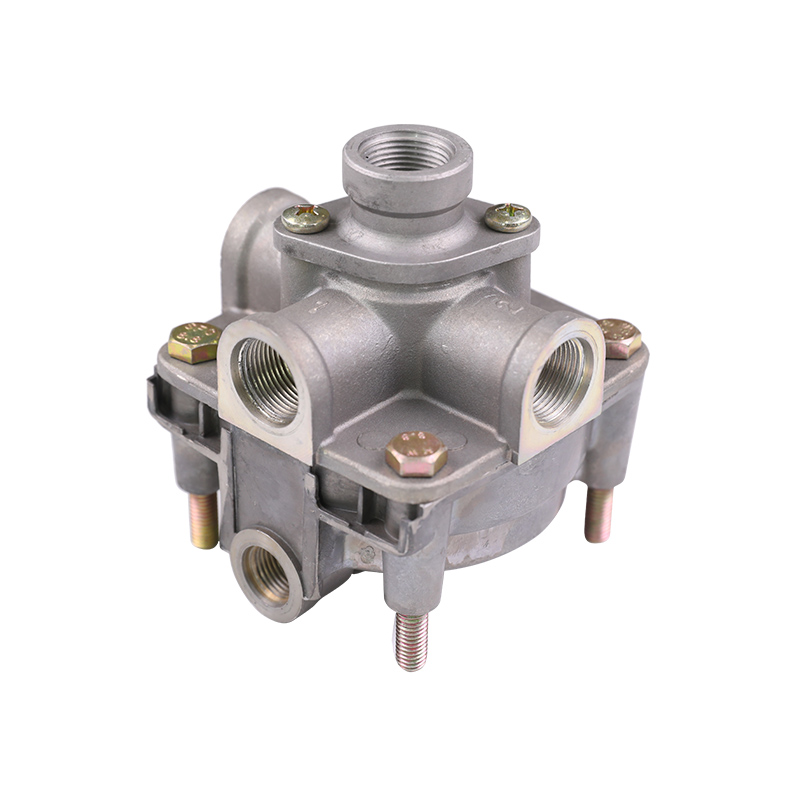

The basic design of a brake air dryer consists of a desiccant filter, a purge valve, and a pressure regulator. The desiccant filter contains a drying agent, usually made of silica gel or activated alumina, that absorbs moisture and contaminants from the compressed air. The purge valve allows the accumulated moisture and contaminants to be expelled from the system, while the pressure regulator controls the pressure of the compressed air that is delivered to the brake system.

One of the main advantages of a brake air dryer is its ability to prolong the lifespan of the brake components. By removing moisture and contaminants from the compressed air, it helps to prevent corrosion and damage to the brake system, which can reduce its effectiveness and lifespan. Additionally, a brake air dryer can help to prevent brake fade, which is a loss of braking power caused by overheating of the brake components.

Another advantage of a brake air dryer is its ability to improve the safety of the vehicle. By ensuring that the brake system operates reliably and effectively, it helps to prevent accidents and improve the overall safety of the vehicle. Additionally, a brake air dryer can help to reduce maintenance costs and downtime by prolonging the lifespan of the brake components.